| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : REXON

Model Number : ZYD-W-100(6000LPH)

Certification : CE, ISO, SGS, CCC

Place of Origin : Chongqing, China

MOQ : 1 Set

Price : Negotiation

Payment Terms : L/C, T/T, Western Union

Supply Ability : 500Sets per Month

Delivery Time : 3~10 working days basd on exact model

Packaging Details : Standard Wooden Cases for Export

Function : Dielectric Oil Treatment

Process Capacity : 1000LPH6000LPH

Power Supply : 380V, 3Phase, 50HZ Or As Required

Color : Green, Blue, Grey, White, Yellow ETC.

More Advantages : Weather Proof | Dust Proof | Enclosed Type

Choices Available : Many Types of Enclosed House

Fully Enclosed Type Vacuum Processing Dielectric Oil Filtration Machine Dewater and Degas from Oil

Technical Parameters:

| Parameters | Unit | ZYD-30 | ZYD-50 | ZYD-100 | ZYD-150 | ZYD-200 | ZYD-250 | ZYD-300 | |

| Flow Rate | L/H | 1800 | 3000 | 6000 | 9000 | 12000 | 15000 | 18000 | |

| Working Vacuum | Mpa | -0.08 ~-0.099 | |||||||

| Working Pressure | Mpa | ≤ 0.3 | |||||||

| Temp Range | ℃ | 20 ~80 | |||||||

| Power Supply | 380V, 50Hz, 3Phase( As per required) | ||||||||

| Working Noise | Db | 60 - 80 (Depended on the configuation) | |||||||

| Heating Power | KW | 30 | 60 | 90 | 135 | 150 | 165 | 180 | |

| Total Power | KW | 35 | 67.5 | 101.5 | 149 | 164 | 198 | ||

| Inlet/Outlet Diam | MM | 25 | 32 | 42 | 50 | 50 | 60 | 60 | |

| Weight | KG | 450 | 550 | 750 | 950 | 1200 | 1850 | 2000 | |

| Size | Length | MM | 1450 | 1450 | 1750 | 1850 | 1950 | 2050 | 2150 |

| Width | MM | 950 | 1000 | 1250 | 1300 | 1350 | 1400 | 1450 | |

| Height | MM | 1700 | 1750 | 1950 | 2000 | 2050 | 2100 | 2150 | |

| AFTER TREATMENT | |||||||||

| Dielectric Strength | KV | ≥ 75-85 | |||||||

| Water Content | PPM | ≤ 3 | |||||||

| Gas Content | % | ≤ 0.1 | |||||||

| Particle Size | μ | ≤ 3 | |||||||

| Cleanliness ≤NAS 1638 Grade 5 | |||||||||

Application:

Fully Enclosed Type Vacuum Processing Dielectric Oil Filtration Machine Dewater and Degas from Oil, Enclosd Type Vacuum Dielectric Oil Treatment Machine and Transformer Oil Purification System ZYD-W-100(6000LPH), Weather-Proof (Enclosed Type) Vacuum Dielectric Oil Filtering Unit and Transformer Oil Purification Machine ZYD-W can quickly remove water, trace water, gas, particles as well as acetylene, hydrogen, methane and other harmful ingredients from oil effectively to improve oil's dielectric strength, effectively making sure electric equipments working safely and normally. It's particularly suitable for treating high-grade transformer oil, super-voltage transformer oil and new transformer oil. It can be used for filtration of more than 110V substation live line work onsite. Meanwhile, it can be used as independent vacuum resource with functions of vacuum drying and vacuum oiling.

Features:

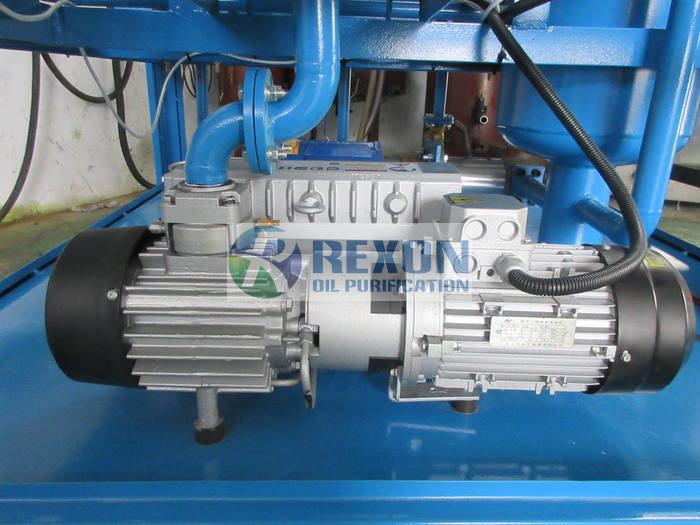

1. Double-stage vacuum system, strong power of vacuum evacuating, ultimate vacuum value ≤ 5Pa.

2. Two vacuum separating chambers, efficient oil film sprayer, increasing separating size and separating time to ensure the dry-level and dielectric strength improving greatly.

3. Duplex-Stereo film evaporation technology, combined with unique and advanced dewatering, degassing components, can rapidly and effectively separate water, gas from oil.

4. Multi-stage precision filtration system, mesh filtration combined with molecular adsorption technologies.

5. Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

6. Double-infrared liquid level sensor, pressure protective system to ensure machine operation easy and safely.

7. Adopt interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

8. Functions of live line work onsite, vacuum drying and vacuum oil filling.

9. Weather Proof designing which can be used outside even in raining weather.

10.Designed for processing oil in workshops, in storage tanks or directly in transformers (energized and de-energized transformers both).

Advantages:

Fully Enclosed Type Vacuum Processing Dielectric Oil Filtration Machine Dewater and Degas from Oil, Weather proof type, which is completely water proof, dust proof, it can protect the machine not to be damaged by raining weather, or in other bad circumstance use. So you can take use of the machine in any weather and many circumstances for any onsite oil filtration project.

Double stage high vacuum oil filtration system

In order to acquire optimal dielectric strength and insulating efficiency inside of transformers and circuit breakers, dielectric oils should be kept absolutely clean up and dry.

REXON designs and builds the most effective, durable, and easily operation high vacuum transformer essential oil purification method available on the market today.

Transformer essential oil remedy plant means Old transformer essential oil is generally mixed with gas, water and contaminants, and also the new transformer essential oil sometimes, the content of the contaminants generally raises fast by time.

So the transformer essential oil remedy machines can remove these associated gases, water and contaminants, and separate them in the essential oil and consider them away.

After treating the essential oil by our essential oil remedy plant, the stabilized essential oil is then again ready to become used in energy transformers.

ZYD double stages vacuum transformer oil purifier is mainly used for removing trace water, gas and impurities from insulating oil, improving the insulating oil performance index.

It is mainly applied to purification of 110KV, 220KV, 500KV, 750KV, 1000KV power transmission equipment insulating oil, also applied to treat low viscosity oils, like insulating oil, turbine oil, and hydraulic oil in the transmission equipment which is lower than 110KV.

If water is saturation in the oil, it appears as the liquid states and stay at the bottom of container. Under the vacuum states, because the less gas content, the water and gas in the oil will be escaped from the oil and evacuated by the vacuum pump. The higher vacuum value (Close to 0 Pa), the higher speed of water molecular volatilization (The latest technology, the Vacuum oil purifier can reach to 1Pa Working vacuum value). The gas and water which dissolved in the oil will become gaseity and exhausted by vacuum pump. The oil temperature affect vacuum oil purifier working efficiency, the higher temperature, the water molecular get more kinetic energy, so it is higher diffused speed of water molecular. But, exorbitant temperature will cause fracture of carbon chain for oil molecular, if that will make oil bad. So we don't suggest the oil temperature excess 80℃. Also the impurity will affect oil dielectric strength, so the vacuum oil purifier requires high filtration precision.

Custom built plants can be provided as per customer's specific requirement, such as more flow-rates. These plants work on low temperature, high vacuum principle. Plants mainly consist of heating, filtration and vacuum system. Heating system aids to the filtration and moisture removal. Filtration systems remove suspended particles down to 1 micron such as rust, dirt, scales, colloidal carbon etc. Vacuum Systems remove moisture (emulsified as well as dissolved) down to < 5 – 10 ppm depending on the working vacuum of the plant.

Spare Parts:

REXON Profile

Chongqing Rexon Oil Purification Co., Ltd is a leading oil purifier manufacturer and oil purification technology development company, we specialized in designing, producing, developing and selling various types of oil purification equipment such as transformer oil purifier, turbine oil purifier, lube oil purifier, hydraulic oil purifier, engine oil purifier, ship oil filtration plant, used cooking oil purifier, centrifuge oil separation purifier and all other industrial oil purification machines. We offered professional oil solutions service and oil purifier machines for world-wide customers near 20 years.

We have a number of national-class oil purification experts and experienced technology engineers, mechanical designers, and machine engineers and well skilled workers, and responsible sales persons as a strong team of our REXON group.

Factory View

Customer Visit

Packing & Delivery:

After Sales Service

►We will help to arrange the transport and shipping for the machine to customer.

►We offer full set documents for customs clearance at customer’s destination port.

►We will offer lifetime technical support for our equipment, free technical upgrade, free or chargeable spare parts supply, etc.

►We offer online service for customers 24 hours everyday. If you have any question while using our machine, you can contact us by online chat software, or by email, phone etc, we will get back to you very soon within 4 hours.

►We will also offer operation training for free in our factory and offer door-to-door service to send our engineer to your place for the machine’s installation service and operation training if you need.

►Installation, Operation and Maintenance details will be in the operation manual booklet and videos which will be sent to you with machine.

►Rexon’s guarantee time is two years for each of our equipment.

Onsite Project

Exhibition

REXON Oil Purification Machines can bring you below:

→Purifying your used oil high efficiently

→Maintain your lube oil always in good status

→Save your old oil replacement cost

→Solve your waste oil disposal problem

→Guarantee your equipment working normally with qualified oil property

→Protect your machinery and plants damaged by oil pollution problems

→Reduce your oil maintenance time, energy and invest on your related machines

→Create a safety and cleaning oil use environment for your machines

→Bring a green oil ideal to the world and save oil energy for all of our generations

|

|

Vacuum Transformer Oil Purifier Unit , Transformer Oil Centrifuging Machine Images |